Goal

My research goal is to reliably predict damage in inelastically deforming structural materials. Damage refers to a variety of phenomena including functional fatigue and fatigue failure. This goal is achieved through two efforts. The first effort is to develop microstructure-sensitive models for damage in metals using an effort combining theoretical and empirical components. The second effort is to quantify the uncertainty in these models. Predictive models for damage together with a quantification of their uncertainty provide a robust tool for component design using these structural materials.

Modeling

Modeling for damage prediction in metals

Deformation response of metals can be complex due to the presence of multiple deformation modes - slip, phase transformation, twinning and other aspects like interaction between the grains, anisotropic mechanical properties and complex loading paths. Microstructural modeling can elucidate the fundamental phenomena defining deformation patterns. Macro scale modeling can provide fast and robust tools to aid in component design process while accounting for the complex deformation mechanisms. Modeling of various inelastic deformation modes can contribute to reliable prediction of damage.

Experiments

In-situ characterization to quantify microstructure and deformation

Synchrotron X-ray diffraction based techniques can quantify deformation and microstructure of metals at multiple length scales. E.g. μXRD can reveal intragranular orientation spread and strains, HEDM can provide grain-scale statistics of orientation and lattice strains and powder diffraction can provide component-scale texture and strains. DIC can provide surface distribution of strains during a deformation test. These techniques together are ideal to inform and validate multi-scale numerical models for damage.

Publications

- Christison A., Paranjape H. M., Daly S. (2025). Plasticity Bridges Microscale Martensitic Shear Bands in Superelastic Nitinol.

- Gao X., Hong D., Paranjape H. M., Zhang W, Anderson P.M. (2023). Berkovich Indentation and the Oliver-Pharr Method for Shape Memory Alloys.

- Paranjape H. M. (2023). Advancing Nitinol Implant Design and Simulation Through Data-Driven Methodologies, Shape Memory and Superelasticity.

- Nagaraja S., Paranjape H. M., Cheng C. P. (2022). Durability of Nitinol Cardiovascular Devices, Shape Memory and Superelasticity.

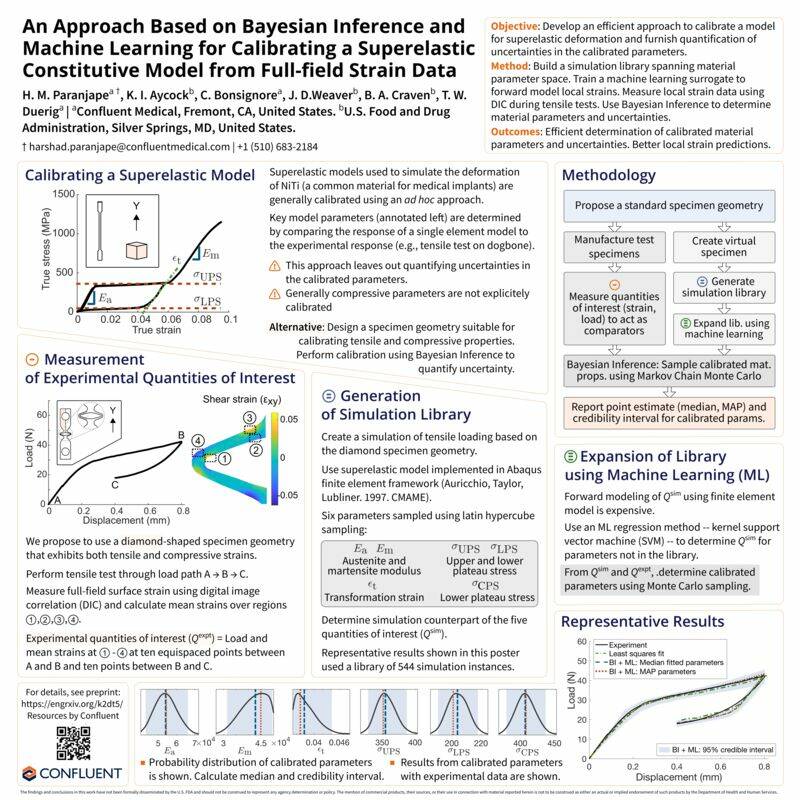

- Paranjape H. M., Aycock K., Bonsignore C., Weaver J. , Craven B. A, Duerig T. W. (2021). A Probabilistic Approach with Built-in Uncertainty Quantification for the Calibration of a Superelastic Constitutive Model from Full-field Strain Data, Computational Materials Science.

- Aycock K., Weaver J. D., Paranjape H. M., Senthilnathan K., Bonsignore C., Craven B. A. (2020). Full-Field Microscale Strain Measurements of a Nitinol Medical Device Using Digital Image Correlation, Journal of the Mechanical Behavior of Biomedical Materials.

- Paul P., Paranjape H. M., Amin-Ahmadi B., Pagan D. C., Chumlyakov Y. I., Brinson L. C. (2020). Heterogeneity and Inelasticity of Deformation in a Notched Martensitic NiTi Shape Memory Alloy Specimen, Acta Materialia.

- Stern J. R., Cheng C. P., Colvard B. D., Paranjape H. M., Lee J. T. (2020). The Triple-Wire Technique for Delivery of Endovascular Components in Difficult Anatomy, Annals of Vascular Surgery.

- Paranjape H. M., Ng B., Ong I., Vien L., Huntley C. (2020). Phase transformation volume amplitude as a low-cycle fatigue indicator in nickel-titanium shape memory alloys, Scripta Materialia.

- Paul P., Paranjape H. M., Tamura N., Chumlyakov Y., Brinson L. C. (2019). In-situ, microscale characterization of heterogeneous deformation around notch in martensitic Shape Memory Alloy, Materials Science and Engineering A.

- Senthilnathan K., Shamimi A., Bonsignore C., Paranjape H. M., Duerig T. (2019). Effect of Prestrain on the Fatigue Life of Superelastic Nitinol, Journal of Materials Engineering and Performance.

- Paul P., Fortman M., Paranjape H. M., Anderson P. M., Stebner A. P., Brinson L. C. (2018). Influence of Structure and Microstructure on Deformation Localization and Crack Growth in NiTi Shape Memory Alloys, Shape Memory and Superelasticity.

- Paranjape H. M., Stebner A. P., Bhattacharya K. (2018). A macroscopic strain-space model of anisotropic, cyclic plasticity with hardening, International Journal of Mechanical Sciences.

- Paranjape H. M., Paul P., Amin-Ahmadi B., Sharma H., Dale D., Ko J. Y. P., Chumlyakov Y., Brinson L. C., Stebner A. P. (2018). In situ, 3D characterization of the deformation mechanics of a superelastic NiTi shape memory alloy single crystal under multiscale constraint, Acta Materialia.

- Paul P., Paranjape H. M., Amin-Ahmadi B., Stebner A. P., Dunand D., Brinson L. C. (2017). Effect of Machined Feature Size Relative to the Microstructural Size on the Superelastic Performance in Polycrystalline NiTi Shape Memory Alloys, Materials Science and Engineering: A.

- Paranjape H. M., Bowers M. L., Mills M. J., Anderson P. M. (2017). Mechanisms for phase transformation induced slip in shape memory alloy micro-crystals, Acta Materialia.

- Paranjape H. M., Paul P., Sharma H., Kenesei P., Park J-S., Duerig T., Brinson L. C., Stebner A. P. (2017). Influences of Granular Constraints and Surface Effects on the Heterogeneity of Elastic, Superelastic, and Plastic Responses of Polycrystalline Shape Memory Alloys, Journal of the Mechanics and Physics of Solids.

- Paranjape H. M., Manchiraju S., Anderson P. M. (2016). A Phase Field/Finite Element Approach to Model Coupled Phase Transformation and Plasticity in Shape Memory Alloys, International Journal of Plasticity.

- Stebner A. P., Paranjape H. M., Clausen B., Brinson L. C., & Pelton A. R. (2015). In Situ Neutron Diffraction Studies of Large Monotonic Deformations of Superelastic Nitinol, Shape Memory and Superelasticity.

- Paranjape H. M., Anderson P. M. (2014). Texture and Grain Neighborhood Effects on Ni-Ti Shape Memory Alloy Performance, Modeling and Simulation in Materials Science and Engineering.

- Ebersole G. C., Paranjape H. M., Anderson P. M., & Powell H. M. (2012). Influence of hydration on fiber geometry in electrospun scaffolds. Acta Biomaterialia.

- Raveendra S., Kanjarla A., Paranjape H. M., Mishra S., Delannay L., Samajdar I., & Van Houtte P. (2011). Strain Mode Dependence of Deformation Texture Developments: Microstructural Origin. Metallurgical and Materials Transactions A.

- Raveendra S., Paranjape H. M., Mishra S., Weiland H., Doherty R. D., & Samajdar I. (2009). Relative Stability of Deformed Cube in Warm and Hot Deformed AA6022: Possible Role of Strain-Induced Boundary Migration. Metallurgical and Materials Transactions A.

Preprints and Non-peer-reviewed

- Paranjape H. M., Aycock K. I., Weaver J. D., Craven B. A., Bonsignore C., Duerig T. W. Quantifying and Propagating Uncertainty in Superelasticity Simulation Inputs, Advanced Materials & Processes.

- Joung A., Pagan D. C., Gilbert J., Vien L., Ong I., Bonsignore C., Paranjape H. M. A Digital Image Correlation Methodology for the Characterization of Cyclic Deformation in Nickel-Titanium Medical Device Fatigue Test Specimens, engrXiv.

Posters

Teaching

Colorado School of Mines

- Spring 2016 | Inelastic Constitutive Relations: Special topics graduate course on the mechanics of inelastic deformation in materials. Combines model development, numerical implementation and experimental verification aspects.

- Fall 2015, 2016 | Solid Mechanics: Co-instructor. Graduate core course in Mechanical Engineering.